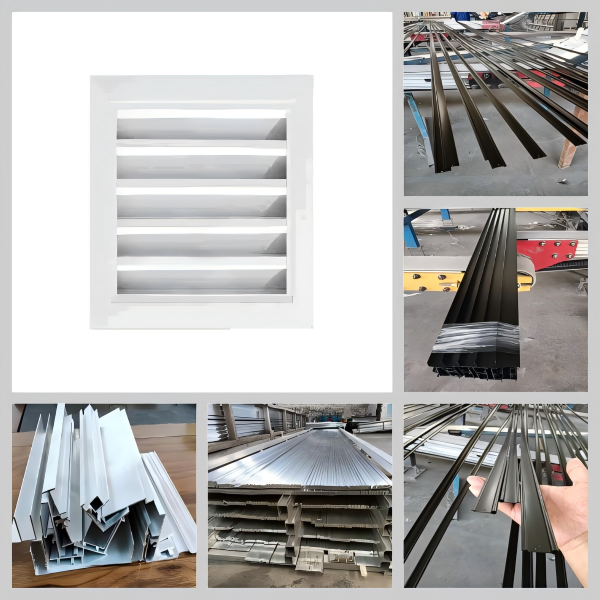

As building energy efficiency retrofits and industrial lightweight demands surge, the aluminum profiles industry is undergoing a significant transformation. Understanding these key trends and selection tips will safeguard your project.

Aluminum profiles, as a core material in modern construction and industrial manufacturing, directly impact project quality and market competitiveness with their quality and performance.

In recent years, China’s aluminum profiles industry has continued to expand in scale. In 2024, national aluminum profile output reached 68.5 million tons, with a market size of 820 billion RMB, a year-on-year growth exceeding 6%.

However, the industry simultaneously faces challenges such as fluctuating raw material prices, upgrading environmental standards, and homogenized competition.

01 Industry Status & Development Trends

China’s aluminum profiles industry is currently at a critical juncture, transitioning from traditional growth models to new kinetic energy. The construction and industrial sectors present a development landscape of “two contrasting scenarios.”

The traditional architectural aluminum profiles market has seen a noticeable slowdown in demand growth due to real estate adjustments. Corporate competition has shifted from scale expansion to quality premium. Leading companies are creating technological barriers in the ultra-low energy consumption building sector by developing high-end products like thermal break aluminum and vacuum glass composite profiles.

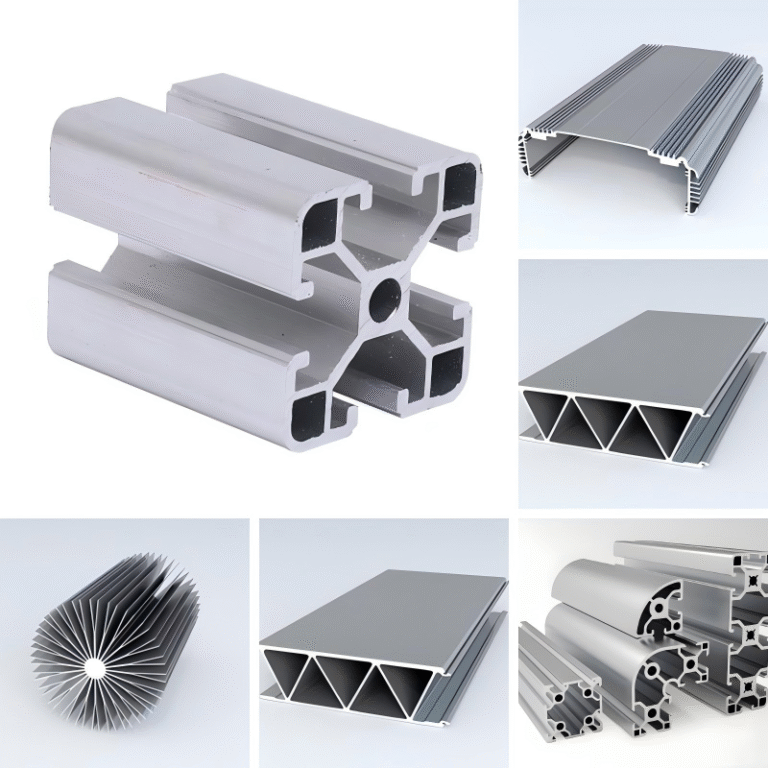

Industrial aluminum profiles, on the other hand, are experiencing explosive growth. The soaring demand for high-performance aluminum profiles from emerging industries like new energy vehicles, photovoltaics, and rail transportation is driving the continuous increase in the share of industrial aluminum profiles.

In the new energy sector, high-value-added products like battery trays and body structural components are rapidly increasing their penetration rate. The photovoltaic industry sees customized demands for products like wind-erosion-resistant profiles and double-sided module frames, spawning niche markets.

02 Common Quality Issues & Customer Pain Points

Quality problems with aluminum alloy profiles have long been a focal point of complaints in the home building materials category. These issues mainly concentrate on the following aspects:

Substandard wall thickness is a critical issue. National mandatory standards require a wall thickness ≥1.2mm for door/window aluminum materials, but many products on the market have a wall thickness of only about 0.7mm. Such “ultra-thin” profiles severely impact the stability and safety of doors and windows.

Low composite film layer bonding strength easily leads to phenomena like hollowing, cracking, or even peeling. This not only affects aesthetics but also reduces the profile’s corrosion resistance and shortens its service life.

Consumer knowledge about identifying building materials is scarce. Many consumers state that due to the required specialized knowledge, they know little about how to distinguish the authenticity and quality of building material products.

After-sales problems are also prominent. Businesses often fail to deliver and install within the promised time; fail to inform in advance about items and standards requiring additional fees; and fail to provide timely maintenance services as stipulated in the contract.

03 Aluminum Profiles Buyer’s Guide

Faced with a dazzling array of aluminum profile products on the market, how can consumers and businesses make smart choices? The following points are crucial:

Pay attention to wall thickness and surface coating: When purchasing aluminum profile doors and windows, carefully observe the wall thickness of the aluminum alloy profile and the thickness of the surface coating. The product should have a good gloss, and the thickness of the aluminum material for doors and windows should not be less than 1.2mm.

Check product information: Pay attention to whether the product’s outer packaging indicates necessary content such as the product name, name and address of the manufacturing unit, production date, product standard number, and quality grade.

Sign a detailed agreement: The agreement should clearly define important clauses such as product quality, environmental protection requirements, delivery deadlines, the scope of free and chargeable items, and liability for breach of contract.

Choose reliable brands: Consumers should not just seek cheap options but should choose formal stores to purchase well-known aluminum alloy door and window brands. Major brands generally use high-quality aluminum materials, and product quality is relatively guaranteed.

Test performance on-site: During the selection process, you can moderately bend the profile by hand. Profiles with greater thickness are not easy to deform, while those with smaller thickness deform easily. Also observe the color of the product; the color of the same aluminum alloy profile should be consistent

04 Common Problems & Solutions for Custom Aluminum Profiles

During the customization of aluminum profiles, customers often encounter several core problems:

Large machining accuracy errors are a common issue in the customization process, possibly due to inferior equipment or insufficient technical experience. Choosing a capable profile manufacturer can ensure machining accuracy errors are controlled within a reasonable range (e.g., within ±0.5mm).

Long delivery times are also a concern for customers. Well-equipped manufacturers typically possess multiple sets of CNC deep processing equipment and professional technical teams, enabling shorter delivery cycles—sometimes as fast as 1 day for delivery and 72 hours for drawings.

Price concerns often arise; many people assume customization must be expensive. Actually, the custom price mainly consists of the aluminum ingot price + processing fee. For large-volume customization, manufacturers can offer discounts.

05 Future Development Trends & Outlook

The aluminum profiles industry will develop towards three main directions in the future:

Green Transformation: Recycled aluminum and green power aluminum technologies are becoming key to breaking industry bottlenecks. The proportion of recycled aluminum in industrial aluminum profiles will significantly increase, forming a hundred-billion-yuan renewable resource market.

Lightweight Breakthroughs: Aluminum alloy density will continue to decrease. New materials like aluminum-lithium alloys and aluminum-magnesium-scandium alloys will achieve large-scale application, promoting weight reduction benefits in the aviation and aerospace fields.

Intelligent Penetration: Industrial robot density will greatly increase, and AI quality inspection technology will deeply integrate into production processes. Leading enterprises are achieving full-process automation through 5G+Industrial Internet technology, boosting per capita产能 (output) while pushing product yield rates to new highs

The next five years will be a critical period for restructuring the aluminum profiles industry. With the sustained growth in demand for high-performance aluminum materials in sectors like aerospace, new energy vehicles, and high-end equipment manufacturing, the industry will accelerate its development towards “greenification, lightweighting, and intelligentization.”

Choosing a high-quality aluminum profile supplier not only ensures project quality but also brings long-term value assurance to your building or product.

Grasping industry trends and selecting reliable partners will help you gain an advantage in the increasingly fierce market competition