In today’s manufacturing and construction industries, the demands on material performance are increasingly stringent: materials must be lightweight to save energy and simplify transportation and installation, yet offer sufficient strength and hardness to ensure structural safety and durability. Aluminum profiles are an outstanding representative that perfectly balances this dichotomy.

So how exactly do aluminum profiles achieve being “light as a feather” yet “strong as iron”? It’s not magic, but rather the result of materials science and precision manufacturing technology. The keys lie primarily in the following three points:

1. Selecting the Right Alloy Formulation: The Foundation of Superior Performance

It all starts with high-quality aluminum alloy. Not all aluminum is created equal; adding specific alloying elements can significantly enhance its mechanical properties.

-

Preferred Series: For structural applications, the 6xxx series (e.g., 6061, 6063) and 7xxx series aluminum alloys are the recognized choices. They form a strengthening foundation by adding elements like Magnesium (Mg), Silicon (Si), and Zinc (Zn) to pure aluminum.

-

Core Advantage: These alloys maintain aluminum’s inherent lightweight特性 (density is only about 1/3 that of steel) while preparing the material for subsequent strengthening processes. The precise ratio of each element is crucial, directly determining the performance ceiling of the final profile.

We strictly control raw material composition to ensure every batch of profiles we provide has a stable and excellent starting point for performance.

2. Heat Treatment Process: The Crucial Alchemical Step

The alloy formulation provides the potential, and heat treatment is the key to fully unleashing this potential. It’s akin to “unblocking meridians” in martial arts novels, allowing the material’s hardness and strength to achieve a leap forward.

-

Core Process: This is primarily accomplished through two stages: solution heat treatment and artificial aging. Solution treatment dissolves the alloying elements uniformly into the aluminum matrix, followed by artificial aging, which allows these elements to precipitate uniformly as fine, strengthening particles that effectively block dislocation movement, thereby greatly increasing hardness.

-

Significant Effect: After precise T6 heat treatment, the hardness of aluminum profiles can easily increase by over 30%, resulting in an extremely high strength-to-weight ratio. This is a core环节 (link: /heat-treatment-process) in our process that ensures our products meet international standards and maintain superior quality.

3. Optimized Design and Precision Extrusion: The Power of Smart Structure

Beyond the material itself, scientific design and manufacturing processes are equally decisive for performance.

-

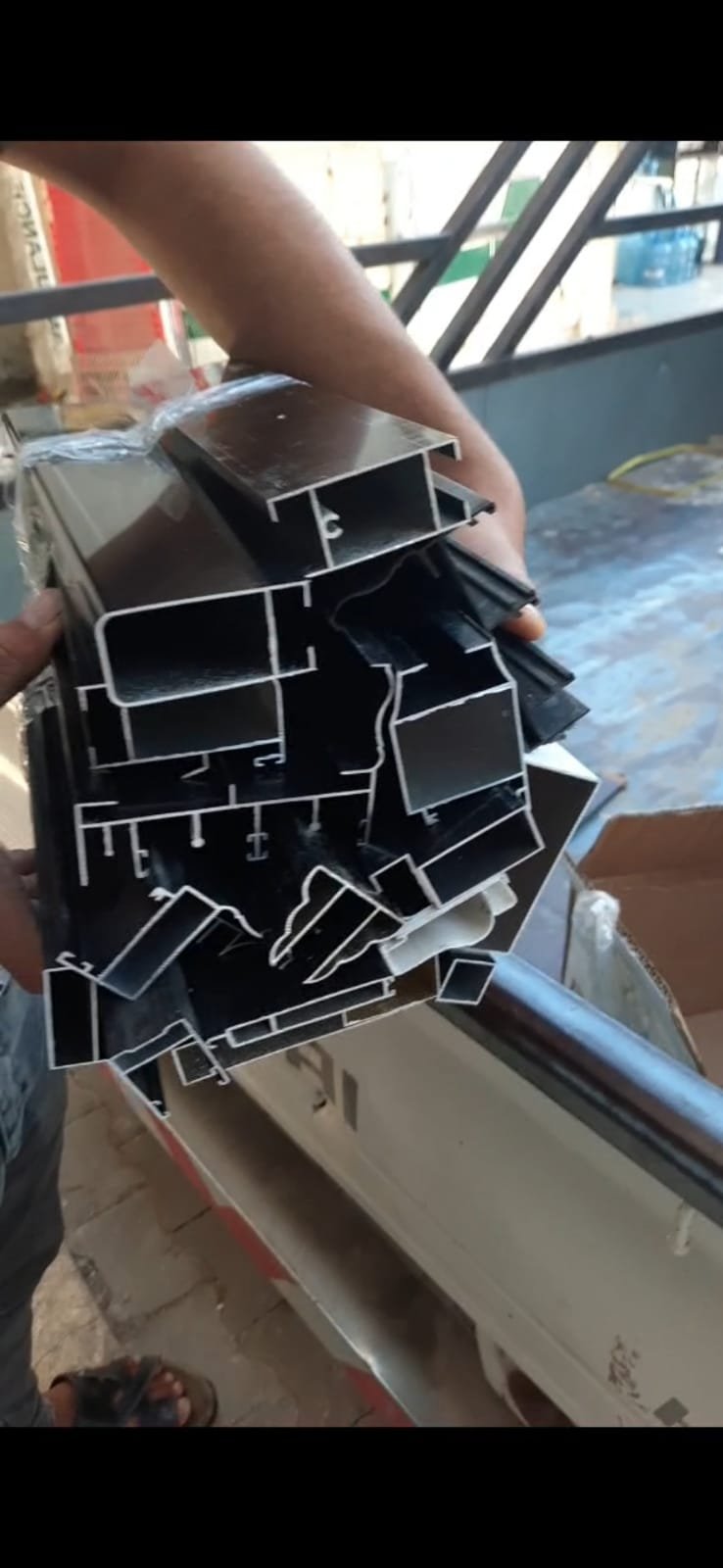

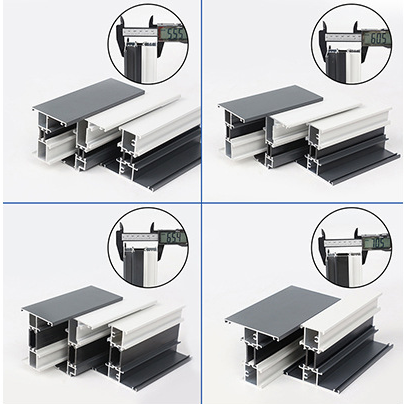

Optimized Design: Leveraging the ease with which aluminum can be extruded into complex shapes, our engineers can design scientific hollow sections, reinforcing ribs, and special-shaped structures. This reduces material usage, further lightening weight while significantly improving the profile’s bending stiffness and overall stability. Explore our custom solutions page to see how we can optimize design for your specific needs.

-

Precision Extrusion: Excellent design requires perfect execution. Through precision dies and strict control of extrusion parameters like temperature and speed, we ensure the profile structure is dense, dimensions are accurate, the surface is uniform, and free from internal defects, guaranteeing consistency and reliability in the final product’s performance.

Conclusion

Superior Alloy + Precise Heat Treatment + Optimized Design & Processing = Lightweight & Strong Aluminum Profiles!

Every high-quality aluminum profile is the result of rigorous and uncompromising control over these three key links. This is the confidence behind our ability to provide clients with lightweight, robust, and reliable aluminum profile products.

Are you facing the following challenges?

-

Seeking a reliable aluminum profile supplier but struggling with unstable product quality?

-

Need special specification profiles, but your current supplier cannot provide customization?

-

Working with tight project deadlines, but suppliers consistently deliver late?

-

Looking to optimize procurement costs and enhance market competitiveness?

We understand your pain points and are dedicated to solving these problems for you.

As a professional aluminum profile manufacturer from China, we focus on providing high-quality custom aluminum profile solutions for global aluminum profile distributors, window and door manufacturers, furniture companies, and more. Our core products include but are not limited to:

-

Window, Door, and Curtain Wall Profiles

-

Shutter, Blinds, and Roller Profiles

-

Cabinet, Wardrobe, and other Home Decoration Profiles

Our Advantages:

-

Deep Customization: Offer flexible product customization based on your drawings or requirements.

-

Superior Quality: Strictly adhere to international standards (e.g., ISO, ASTM), employing the advanced technologies described above.

-

On-Time Delivery: Efficient production management systems ensure orders are delivered on schedule.

-

Cost Optimization: Through efficient production management and economies of scale, we can help you significantly reduce procurement costs. For instance, last month we successfully assisted a distributor in South Africa in reducing their procurement costs by approximately 15%.

If you are looking for a stable, reliable, and cost-effective supply of aluminum profiles, please contact us now. Let us become your powerful backend support, helping you expand your market.

WhatsApp: +86-15717420909

Email: landyqfy@gmail.com