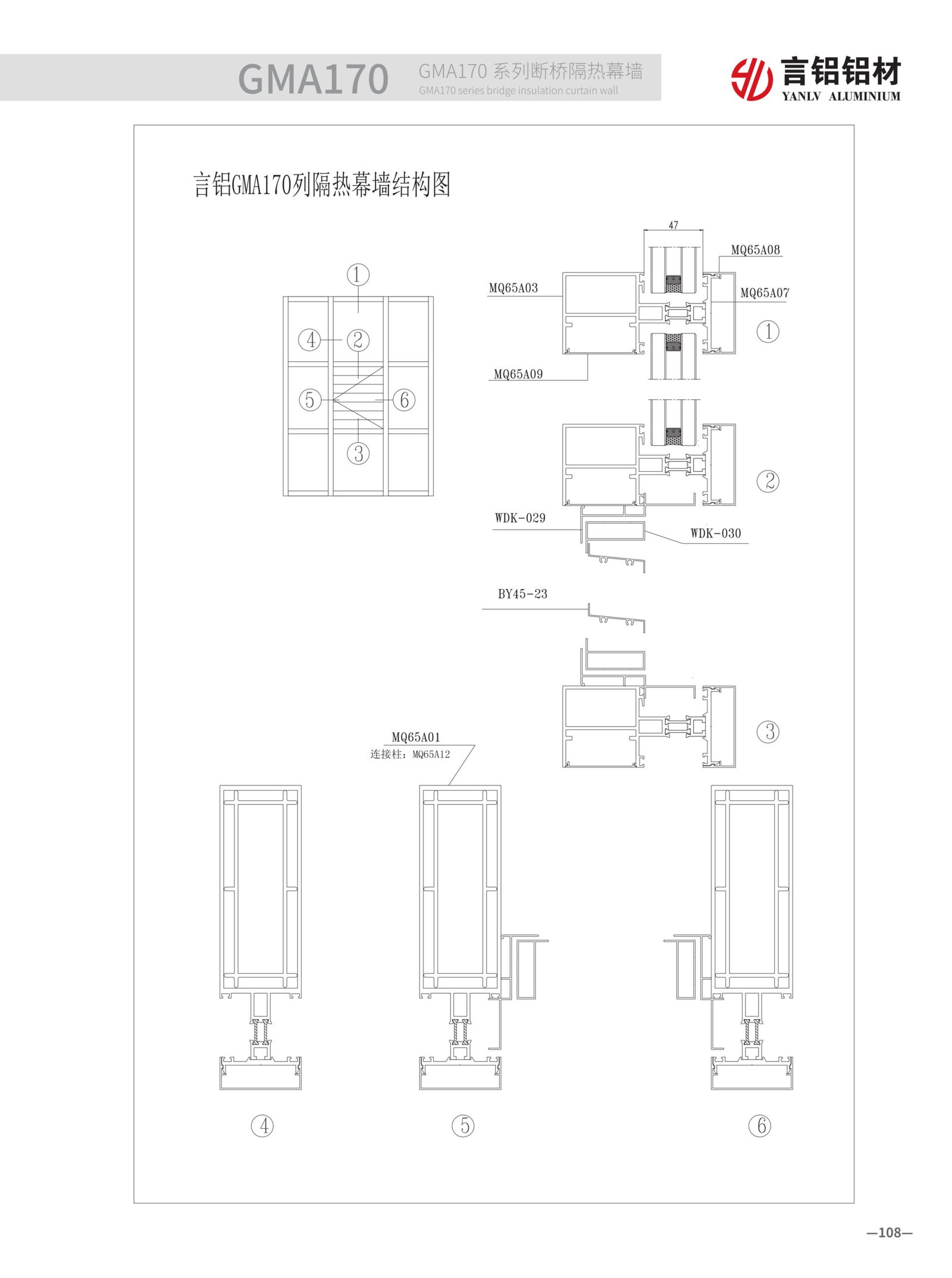

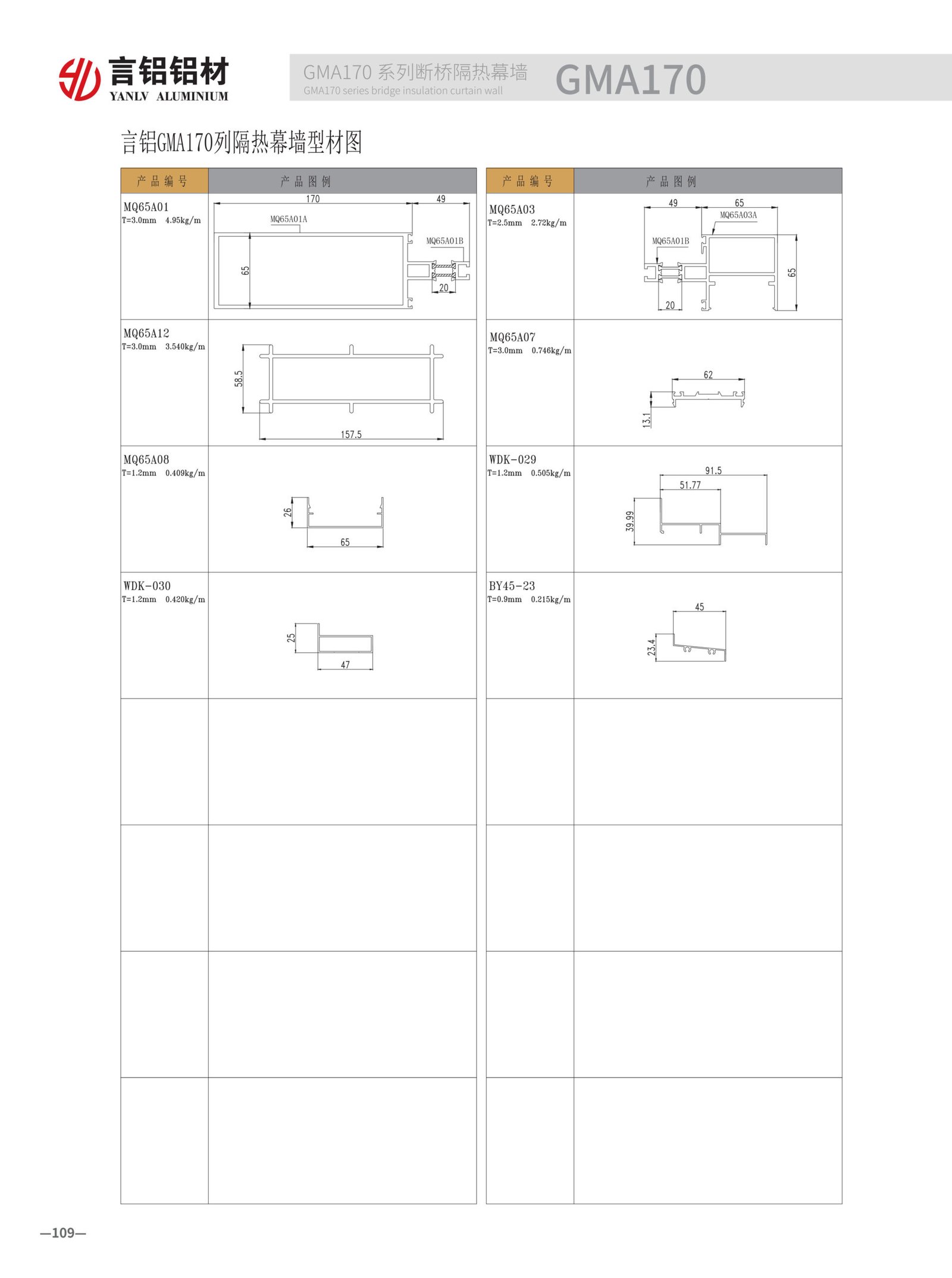

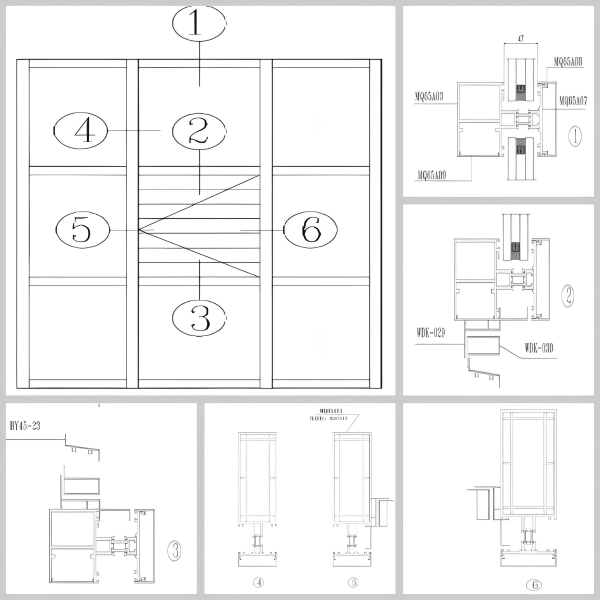

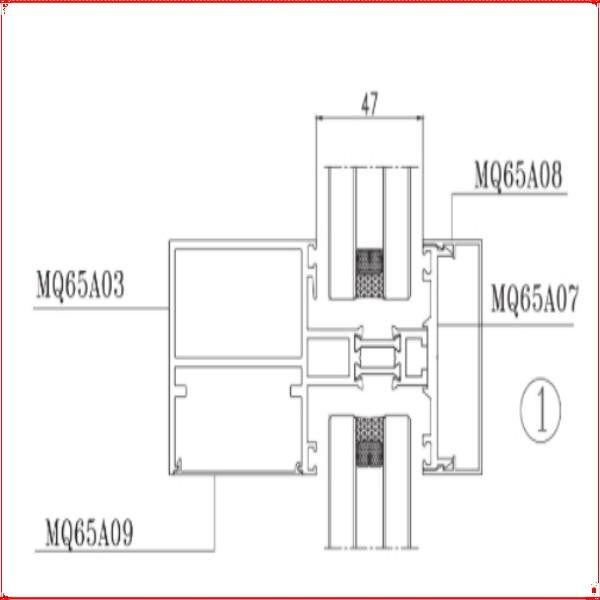

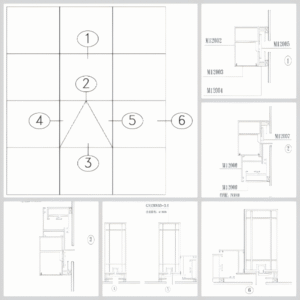

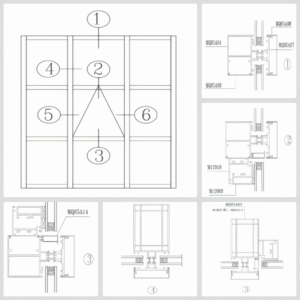

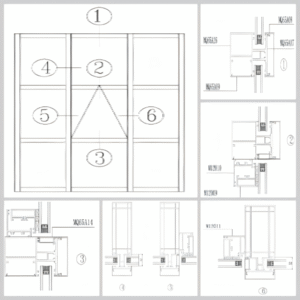

GMA170 series thermal insulation curtain wall

Thermal Break Curtain Wall Profiles|Energy Saving|Thermal Insulation|System Solution

Professional thermal break curtain wall profiles! PA66 nylon thermal break technology, U-value as low as 0.8W/m²·K, significant energy saving. Custom projects supported, free thermal calculation, 20-year warranty!

→Get a free layout plan & quote now!

Description

Key Selling Points:

Break Thermal Barriers! Innovative thermal break curtain wall profiles providing energy-efficient building enclosure solutions

Thermal Insulation Pain Points:

High energy consumption, costly air conditioning?

Thermal bridging causing condensation and mold?

Failing energy efficiency compliance?

Poor summer insulation and winter heat retention?

Inadequate sound insulation?

Your Energy-Saving Solution:

ThermalBreak Series Curtain Wall Profiles with European standard PA66GF25 glass fiber reinforced nylon thermal barriers, reducing thermal conductivity by 60%, creating green building facades

Core Advantages:

❄️ Excellent Thermal Performance

Pain: Energy waste

Solution: Multi-chamber thermal break design, U-value ≤0.8W/m²·K, 40% energy saving

Keywords: thermal break aluminum

🔇 Superior Sound Insulation

Pain: Noise pollution

Solution: Multi-chamber structure + sealing system, sound insulation up to 35dB

Keywords: acoustic aluminum profiles

🏗️ Structural Integrity

Pain: Safety concerns

Solution: 6063-T5 aluminum alloy, tensile strength ≥160MPa, reliable safety

Keywords: high-strength aluminum

🌧️ Moisture & Condensation Resistance

Pain: Condensation and mold

Solution: Equal pressure chamber design, prevents condensation effectively

Keywords: condensation-free aluminum

Technical Support:

✅ Free thermal calculation

✅ Energy compliance reports

✅ 20-year quality guarantee

landyqfy@gmail.com –

“As the project manager for the commercial building, we selected the GMA170 insulated curtain wall system. The most immediate impact was a reduction in air conditioning energy consumption of over 30%. Even under extreme temperature fluctuations, condensation has disappeared indoors. The installation process was extremely smooth, and the precision of the profiles and the integrity of the supporting system exceeded our expectations. Most importantly, the building’s exterior maintains a modern, clean aesthetic while achieving LEED certification. This system truly strikes a perfect balance between aesthetics and performance, delivering long-term energy savings to the owner.”