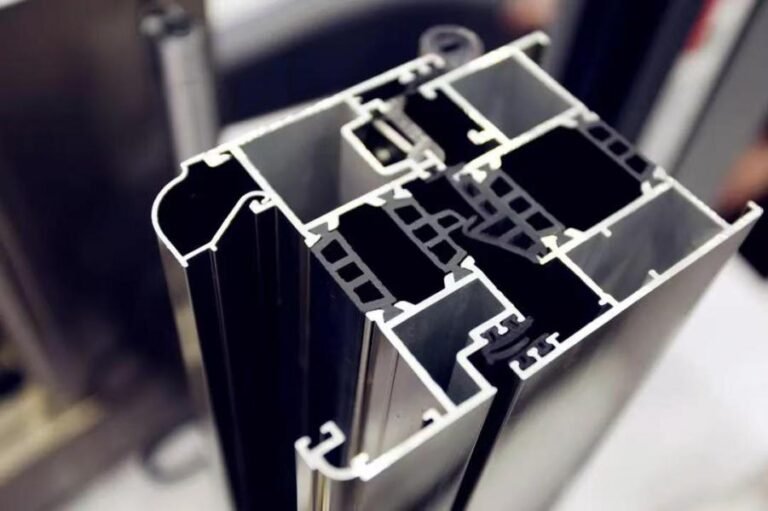

In the architectural aluminum profile industry, weighed settlement and theoretical settlement are two common transaction methods. Discrepancies between these weights often lead to disputes. As a professional manufacturer, Guangyan Aluminum (www.guangyanalu.com) identifies three primary causes based on extensive technical experience: wall thickness deviation, surface coating variation, and packaging material weight. This article focuses on the impact of wall thickness deviation and how to control it, helping clients minimize errors and achieve fairer settlements.

Aluminum Profile Weight Difference: The Primary Cause – Wall Thickness Deviation

The slight difference between the actual wall thickness and the theoretical design thickness directly causes the discrepancy between weighed and theoretical weight.

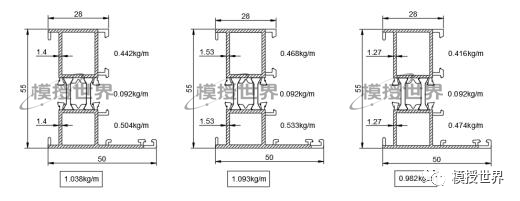

According to the Chinese Standard GB/T5237.1, for profiles with a circumscribed circle diameter ≤100mm and nominal wall thickness <3.0mm, the high-precision tolerance is ±0.13mm. Taking a window frame profile with a nominal wall thickness of 1.4mm as an example:

-

Theoretical weight per meter: 1.038 kg/m

-

Weight per meter with +0.13mm deviation: 1.093 kg/m (difference: 0.055 kg/m)

-

Weight per meter with -0.13mm deviation: 0.982 kg/m (difference: 0.056 kg/m)

Calculated based on approximately 963 meters per ton of profile, the weight difference per ton can reach 53 kg. Note that the above example only considers the deviation at a single section. If the deviations across all sections of the profile are combined, the total difference can be as high as 93 kg (Calculation: 0.13/1.4*1000).

Therefore, wall thickness deviation is a critical technical parameter determining the final weight. In actual production, due to mold wear, the wall thickness of profiles produced early from the same mold is thinner and gradually increases in the middle and later stages. This means the weighed weight of products from the same order dynamically changes from “lighter than theoretical weight” to “heavier than theoretical weight.”

Guangya Aluminum is committed to controlling wall thickness deviation within the optimal range through precise production processes and strict mold management, thereby helping clients reduce settlement risks. In the next article, we will discuss the impact of surface coating and packaging on weight