For decades, curtain wall aluminium systems have defined the skylines of our modern cities. As a leading Chinese manufacturer of aluminum curtain wall profile solutions, GuangYan Aluminum operates at the intersection of architectural ambition, material science, and precision engineering. A modern aluminum curtain is far more than a decorative facade; it is a sophisticated, performance-driven building skin that dictates a structure’s energy efficiency, durability, and aesthetic character. This article provides a manufacturer’s deep dive into the innovation, engineering, and future trends of aluminum profiles for curtain walls, offering architects, developers, and contractors the insights needed to specify with confidence.

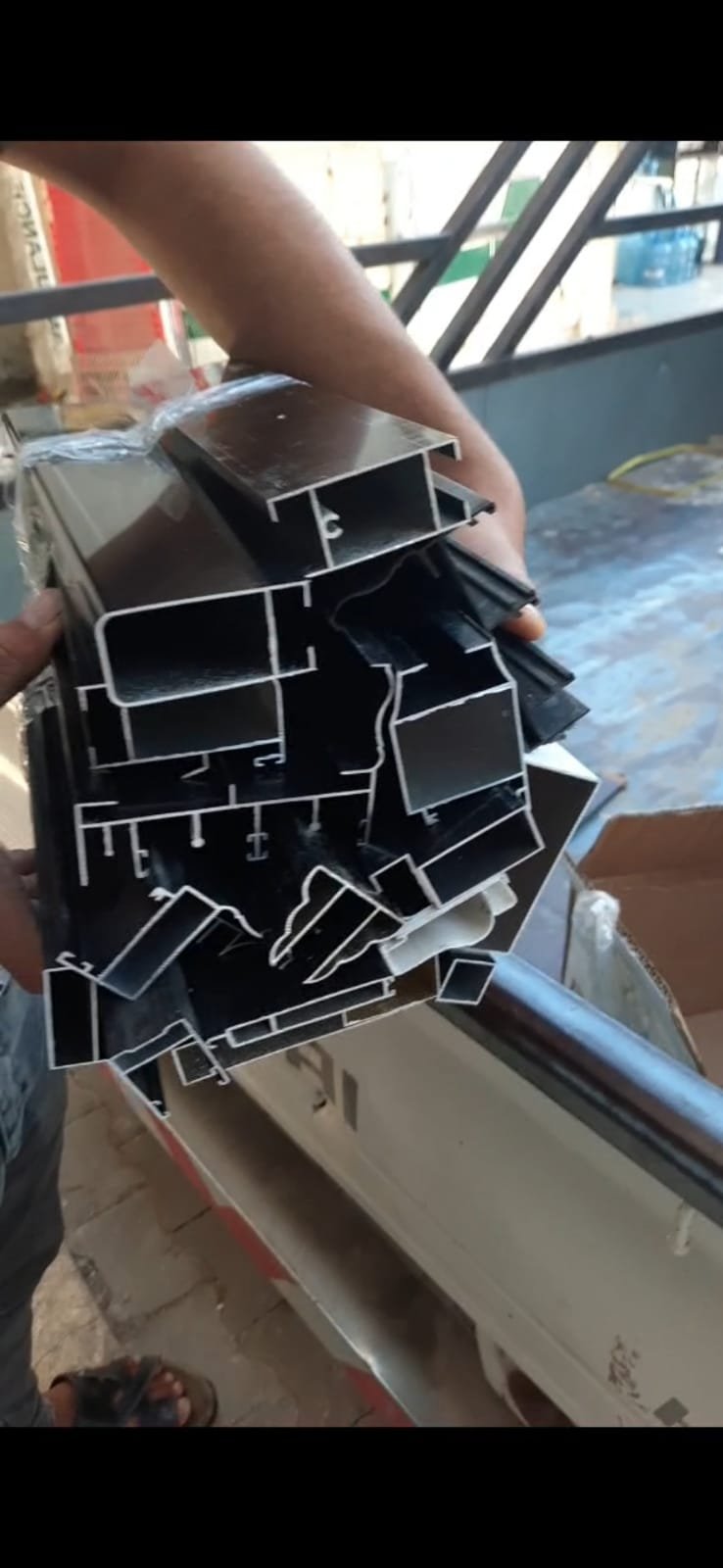

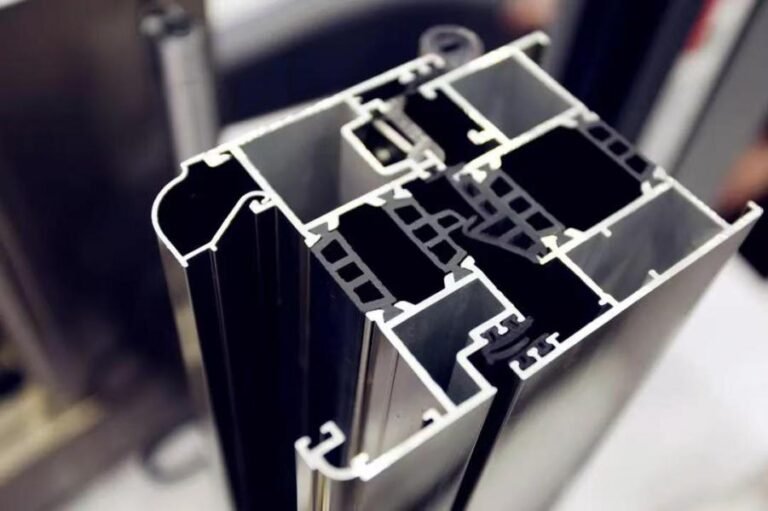

The Engineered Core: Deconstructing the Aluminum Curtain Wall Profile

At its heart, every high-performance aluminum curtain is a system of intricately engineered profiles. The aluminum curtain wall profile is not just a piece of metal; it is a component designed for specific structural, thermal, and water-management functions.

Material Science and Manufacturing Excellence

We utilize 6000-series aluminum alloys, primarily 6063 and 6061, known for their optimal combination of extrudability, strength, and corrosion resistance. The extrusion process itself is where potential is unlocked. Through precise die design and controlled extrusion, we create profiles with complex internal chambers that facilitate thermal breaks, condensation management, and integrated glazing channels.

Advanced systems, like the MN50 stick system, incorporate micro-condensation channels and high-water insulation to actively manage moisture and prevent infiltration. This level of performance is not accidental but is the result of rigorous R&D and manufacturing control, ensuring every aluminum curtain wall profile meets international standards such as GB 5237-2008 and EN 755.

The Critical Role of Thermal Performance

A standard aluminum curtain wall profile is a conductor of heat, which is a major challenge for building energy efficiency. The solution lies in thermally broken profiles. This involves using a polyamide bar to separate the interior and exterior aluminum profiles, dramatically reducing thermal transfer. The global push for sustainable construction is the strongest driver for such advanced systems, which can improve building energy efficiency by 25-30% compared to conventional walls.

Market Trajectory: Why Aluminum Curtain Walls Are the Global Choice

The global aluminum curtain market is on a steady growth path. The structural glazing segment alone, which relies heavily on specialized aluminum profiles, was valued at USD 9,475 million in 2025 and is projected to reach USD 12,486 million by 2032, exhibiting a Compound Annual Growth Rate (CAGR) of 4.1%. This growth is fueled by several key factors:

-

Urbanization and Commercial Construction: Rapid urban development, particularly in the Asia-Pacific region, is driving demand for commercial high-rises that utilize these sleek, modern facades.

-

Demand for Energy-Efficient Buildings: Governments worldwide are implementing stringent energy codes, making high-performance, thermally broken aluminum profiles for curtain walls a default specification for new projects.

-

Aesthetic Flexibility: The desire for all-glass, seamless exteriors in corporate, hospitality, and institutional buildings makes curtain walls the preferred choice. Structural glazing, enabled by robust aluminum framing, allows for 30-40% larger glass spans than traditional methods.

Beyond the Basic Frame: Innovation in Aluminum Profile Design

The future of curtain wall aluminium lies in smarter, more integrated profiles. We are moving beyond simple framing members to multi-functional components.

Integration of Smart and Sustainable Technologies

The next generation of aluminum curtain wall profile systems is being designed to accommodate integrated technologies. This includes:

-

Photovoltaic Glazing Systems: Profiles are being engineered to support and connect building-integrated photovoltaic (BIPV) cells, turning the facade into an energy-generating asset.

-

Smart Glass Compatibility: As dynamic glass that can tint on demand becomes more common, profiles are being optimized to house the necessary wiring and support mechanisms.

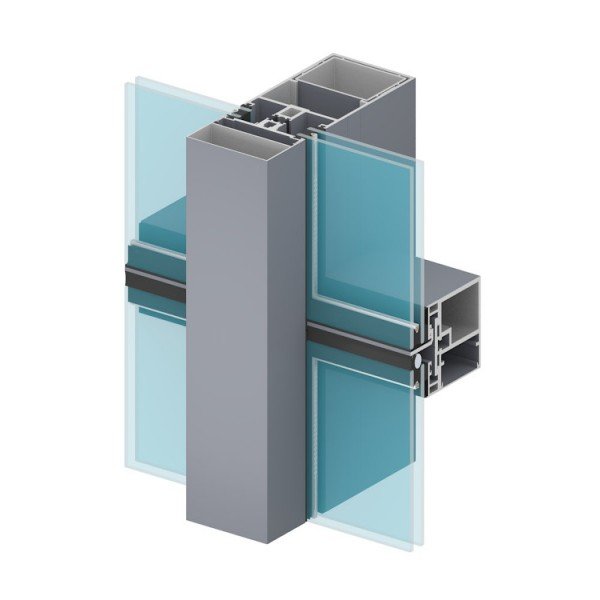

Pushing the Boundaries with Structural Glazing

Structural glazing represents the pinnacle of modern aluminum curtain design. This system uses high-performance silicone sealants instead of mechanical fasteners to bond glass to the hidden aluminum curtain wall profile, creating a completely smooth, uninterrupted glass facade. This demands extreme precision in the manufacturing of the aluminum substrates to ensure perfect bonding and long-term structural integrity.

A Manufacturer’s Guide to Selecting the Right Aluminum Profiles for Curtain Walls

Selecting the correct aluminum profiles for curtain walls is a critical decision that impacts the project’s cost, timeline, and performance.

Key Selection Criteria

-

Alloy and Temper: For most curtain wall applications, 6063-T5 or T6 temper alloys provide the best balance of strength and workability.

-

Surface Treatment: Options include anodizing for a durable metallic finish or powder coating for a wide range of colors. QUALANOD and QUALICOAT certifications are reliable indicators of quality.

-

Thermal Performance: Always specify thermally broken profiles for any climate-controlled building. Verify the thermal performance data and certifications.

-

Structural Capabilities: The profile design must be validated through engineering analysis to withstand the project’s specific wind loads, dead loads, and seismic requirements.

The Value of Collaboration

The most successful projects result from early collaboration between the design team and the manufacturer. By engaging with us during the design phase, we can advise on the most efficient aluminum curtain wall profile solutions, potentially customizing profiles to reduce weight, cost, or improve aesthetics, much like the 18 different mullion methods offered in the MN50 system.

The Sustainable and Intelligent Future of Curtain Wall Aluminium

The trajectory for curtain wall aluminium is pointed firmly towards greater sustainability and intelligence. The industry is focused on increasing the use of recycled aluminum in aluminum curtain wall profile production, further reducing the embodied carbon of these systems. We are also developing profiles that are easier to disassemble and recycle at the end of the building’s life, supporting a circular economy.

Furthermore, the facade is evolving into a responsive building organ. Future aluminum profiles for curtain walls may contain integrated channels for sensors that monitor weather, temperature, and structural stress, feeding data to the building’s management system to optimize performance in real-time.

Conclusion: Building Higher and Smarter with Advanced Aluminum Solutions

The aluminum curtain is a testament to human ingenuity in construction. From its functional beginnings, it has evolved into a high-tech building skin that protects, insulates, and inspires. For architects and developers, understanding the depth of engineering within each aluminum curtain wall profile is key to unlocking its full potential.

As a manufacturer committed to innovation, GuangYana Aluminum is not just a supplier of aluminum profiles for curtain walls but a partner in creating the next generation of iconic, efficient, and intelligent buildings.

China’s Aluminum Profile Expert: Quality Solutions, Competitive Edge

Engineered to cut your procurement costs by 30%+. Our range delivers precision performance for:

✓ Industrial Load-Bearing Systems

✓ Energy-Efficient Windows & Doors

✓ Architectural Curtain Walls

✓ Advanced Thermal Break Tech

Military-grade QC + agile supply chain power your global growth